Safety routines in the ANA Futura freezer facility

Safety in the freezer facility is a high priority in ANA Futura. If you have biological samples stored in the freezer facility, you can be sure that systems and procedures are continuously updated to keep your samples safe.

Important!

We all depend on that each one of us, report any problem in the freezer facility to the service team as soon as it happens.

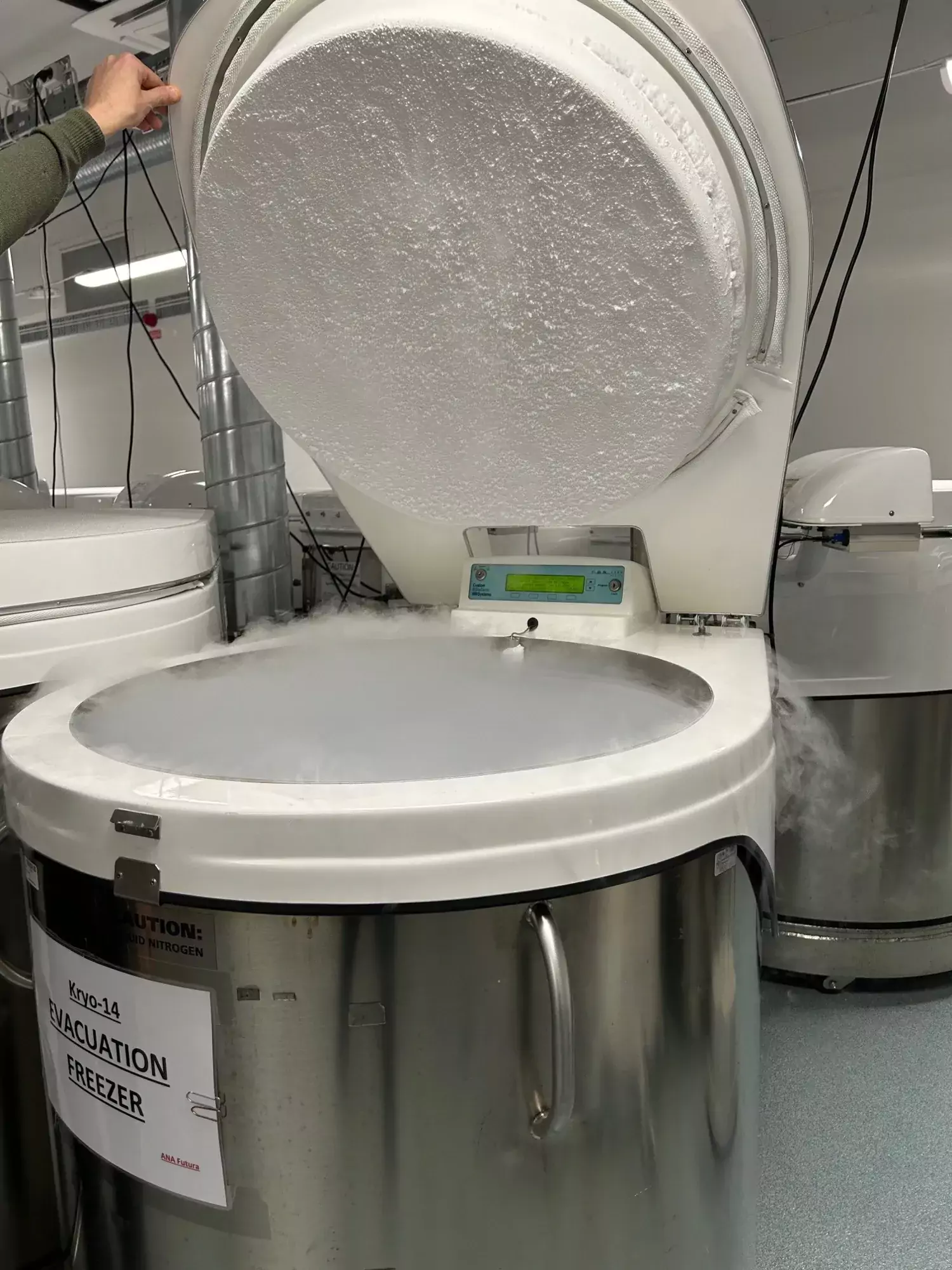

Cryo freezer in ANA Futura.

Photo: Christina Sundqvist

Safety actions

These are the actions we have implemented to keep our isothermal freezers/low temperature freezers safe:

- Regular physical monitoring of all isothermal freezers/low temperature freezers in the freezer facility and the main liquid nitrogen tank (outside).

- Regular digital monitoring of all isothermal freezers/low temperature freezers via the online freezer alarm system (i.e. SCADA).

- Prior to every weekend/holiday, all isothermal freezers/low temperature freezers are checked physically.

- After each weekend/holiday, all isothermal freezers/low temperature freezers are checked physically.

- Regular test-runs of the alarm system (i.e. SCADA) for functionality.

- Physical inspection of the freezer facility after power-outages, district cooling-outages etc.

- Maintenance of SCADA by the provider of the alarm system.

- Maintenance of the facility and safety systems by the company who built the freezer facility.

Transportation of liquid nitrogen

To get access to the Cryo SafeFill cabinet, you need an introduction to both the filling cabinet and the elevator (for transportation). More information on the page about access to the Cryo SafeFill cabinet.