Ventilated workplaces

The risk assessment for the method will determine whether ventilated workplaces are necessary and which type should be used. It is important to distinguish between biological safety cabinets, clean benches (LAF benches), and ventilated workplaces designed for chemical handling, such as fume cupboard, suction table, and spot extractor.

Biological Safety Cabinet

A biological safety cabinet is designed for work with microorganisms. It includes features such as HEPA filters to purify the outgoing air to protect the user. There are different types of biological safety cabinets; class 1 provides only personal protection, while class 2 provides both personal and product protection. In a class 2 biological safety cabinet, most of the air circulates within the cabinet, with HEPA-filtered air blowing from the top down over the work surface, thereby protecting samples as well.

Biological safety cabinets are often not connected to the external ventilation system (process ventilation), they only protect against microorganisms and are not suitable for work with hazardous chemicals. If a biological safety cabinet is also to be used for work with hazardous chemicals, it must be connected to the external ventilation system (process ventilation) to protect the user.

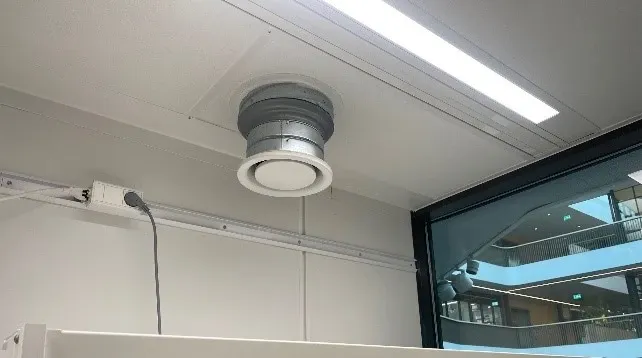

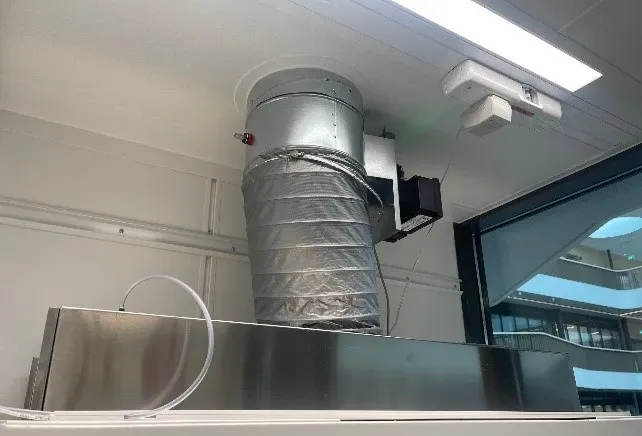

You can see if a biological safety cabinet is connected to the external ventilation system or not by the connections above the cabinet (see images below).

Important considerations when using:

- Move and work slowly to avoid turbulence.

- Work at least 15 cm from the front edge of the safety cabinet.

- Do not overcrowd the safety cabinet, as this increases turbulence.

- After finishing work, clean thoroughly and do not leave any items.

- Turn off the safety cabinet after finishing work to minimize energy consumption.

More information on the different biological safety cabinets can be found in the Swedish Work Environment Authority’s PM on biological safety cabinets (only in Swedish).

Clean Bench/LAF Bench

A clean bench/LAF bench is a ventilated workplace that only provides product protection. The airflow comes out of the bench towards the user to protect the samples from contamination.

Note: Do not use for work with hazardous chemicals or microorganisms!

If you are unsure whether it is a biological safety cabinet or a clean bench, you can test it by holding a piece of paper at the work surface and observing which way the paper moves.

Ventilated workplace for chemical handling

A ventilated workplace designed for chemical handling (e.g., fume cupboard, suction table, and spot extractor) does not have HEPA filters to protect against hazardous microorganisms in the air. Therefore, when using both chemicals and microorganisms, biological safety cabinets connected to the external ventilation system (process ventilation) should be used. For more information, see the section on biological safety cabinets.

Note: It is not recommended to combine a spot extractor with a suction table in the same room, as their flows can counteract each other, resulting in unprotected work.

Fume Cupboard

Suitable for working with hazardous vapours and gases, as well as other fuming materials such as dry ice or liquid nitrogen. Work can be performed at both low and high temperatures.

Important considerations when using:

- Do not clutter the fume cupboard with unnecessary equipment or chemicals, as this disrupts the airflow.

- It is not allowed to use a fume cupboard as a storage place for chemicals or chemical waste.

- The fume cupboard sash should not be open above the specified safety height (usually 30 cm), and work should be done at least 15 cm behind the sash.

- Never place your head inside a fume cupboard.

- Avoid rapid movements and do not raise the sash too quickly.

- The airflow is 0.5 m/s into the cupboard (for most fume cupboards).

- The sash must be lowered when not working in the fume cupboard to minimize energy consumption.

Suction Table

Suitable for heavy vapours, heavy gases, or for weighing powders, but not for work involving heating or volatile chemicals.

Important considerations when using:

- Work within 15 cm from the surface and in the centre of the table (10 cm from the front edge). Higher than 15 cm the air suction is insufficient to protect you.

- Do not cover more than 1/3 of the ventilated area, and keep it clean from dust and chemical residues.

- Force the ventilation when you are using the equipment and keep it at basal level when not working.

Spot extractor

Suitable for local emission of vapour or particles from, for example, equipment in the laboratory that is not suitable for a fume cupboard but requires protective ventilation. The ventilated area corresponds only to the diameter of the local exhaust. Larger areas require larger diameters. Provides limited protection and is intended for work at both low and high temperatures.

Important considerations when using:

- Place the spot extractor as close to the source of contamination as possible. It should not be more than 15 cm away from the source.

Here is a film from the University of Gothenburg about ventilated workplaces available (subtitled in English, length approx. 14 min).